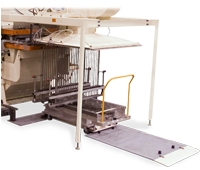

Rotary Stacker System

The Rotary Type Stacking System allows the efficient production and proper orientation of fins as they are produced on our fin line. The rotary system will move a completed stack from under the suction hood to a position for manual unloading, at the same time placing an empty set of tooling under the hood so fin production can be resumed. Removal of the fins from one station can safely take place while the press is filling another.The elevator option is useful in aiding the location, stacking, and removal of fins with smaller collar diameters (5/16 inch or 7mm, for instance).

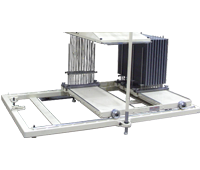

Shuttle Stacker System

The Shuttle Type Stacking System allows the efficient production and proper orientation of fins as they are produced on our fin line. This system will move a completed stack from under the suction hood to positions left or right of the fin line for manual unloading, at the same time placing an empty set of tooling under the hood so fin production can be resumed. Removal of the fins from one station can safely take place while the press is filling another.

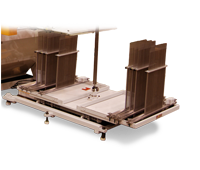

Cart Stacker System

The Cart Type Stacking System is an innovation in fin handling whose time has come. Completed stacks of fins can quickly and efficiently be replaced by empty carts and fin production resumed. Exact locating of the carts in the stacking position is assured by a nesting and locking plate. Wheeled carts then allow the stacks of fins to be delivered directly to lacing areas or placed in an inventory or ‘kanban’ location for further processing.